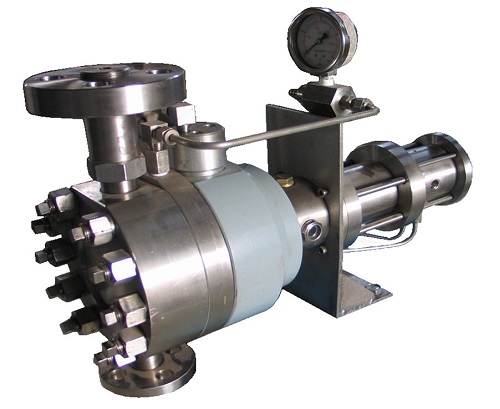

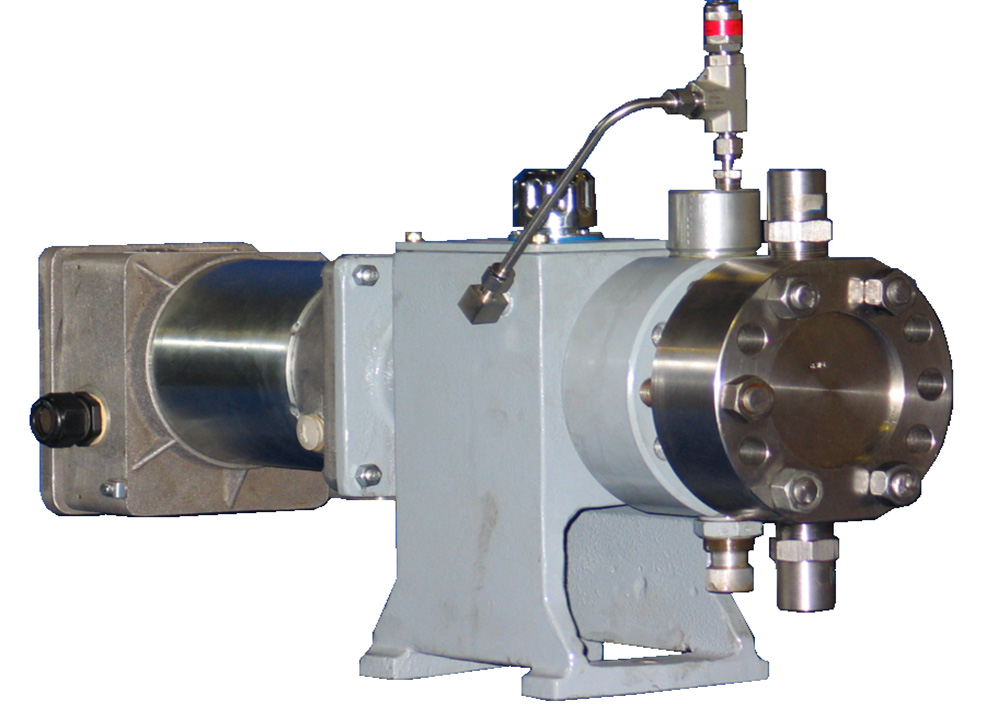

NEEV air driven chemical injection pumps are positive displacement, reciprocating pumps with superior durability, specifically designed for demanding chemical delivery for oil and gas production enhancement. Chemical heads are available with a plunger (ceramic, stainless or hastelloy C) or leak-proof stainless steel diaphragm.

Adjustable plunger packing: Chevron-style packing replaces spring loaded seals. Leakage can therefore be stopped simply by tightening packing nut.

Intrinsically safe pneumatic operation: no costly explosion proof enclosure

No springs or diaphragms in the air motor: Fewest parts to wear or break

Highest turndown ratio: pump volume delivery adjustability ratio over 100:1

Double-acting air motor: Develops powerful suction stroke and eliminates break age-prone return spring

Discrete chemical head: Physically separated head prevents hazardous chemicals from entering air motor and becoming airborne

Maximum reliability: Longest time between failures in the industry

No positive suction pressure required on chemical supply: Mount pumps above tank if needed

API 675 compliant Pumps may be duplexed: For nearly continuous flow

Choice of chemical heads: Plunger or leak-proof stainless steel diaphragm

Air/Gas supply recovery – Optional recovery of exhaust gas eliminates pollutants, even under high back pressure

Adjustable plunger packing: Chevron-style packing replaces spring loaded seals. Leakage can therefore be stopped simply by tightening packing nut.

Intrinsically safe pneumatic operation: no costly explosion proof enclosure

No springs or diaphragms in the air motor: Fewest parts to wear or break

Highest turndown ratio: pump volume delivery adjustability ratio over 100:1

Double-acting air motor: Develops powerful suction stroke and eliminates break age-prone return spring

Discrete chemical head: Physically separated head prevents hazardous chemicals from entering air motor and becoming airborne

Maximum reliability: Longest time between failures in the industry

No positive suction pressure required on chemical supply: Mount pumps above tank if needed

API 675 compliant Pumps may be duplexed: For nearly continuous flow

Choice of chemical heads: Plunger or leak-proof stainless steel diaphragm

Air/Gas supply recovery – Optional recovery of exhaust gas eliminates pollutants, even under high back pressure

Characteristics

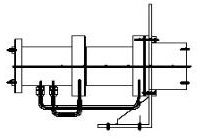

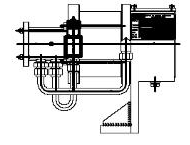

- Reciprocating dosing pump, gas/pneumatic driven with variable stroke

- Stroke adjustment : manual / local , Automatic/remote (4-20mA, 3-15psi)

- Maximum stroke length : 76mm

- Packed plunger liquid end

- Diaphragm liquid end

- hydraulically actuated PTFE diaphragm

- Materials: SS 316,316L ,304, 304L, Alloy steel, PVC, PVDF, PTFE

- Internal safety valve

- Custom designed “special” liquid ends

- Max dimension: Length: 495mm, width: 245mm, height: 400mm

- Driver power supply : 2-10 barg

- Large variety of protection and insulation

Performances

- Packed plunger & PTFE diaphragm liquid end

- Flow rate: from 0.01 l/h to 63 l/h

- Pressure: from 1barg to 1000 barg

- Maximum temperature for pumped fluid: +90 ºC for metallic liquid end +40 ºC for plastic liquid end

p1

p2

All NEEV pumps conform to API 675 and they have a maximum temperature of 120ºC (Up to 300 ºC with special designs).